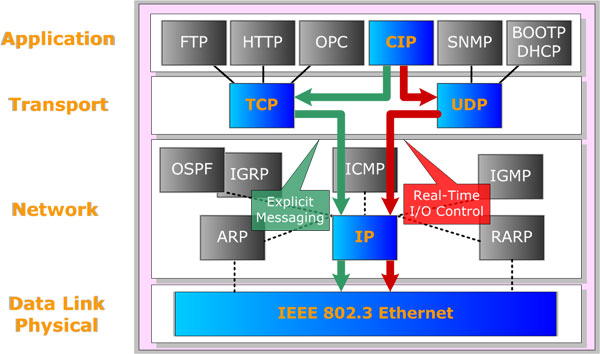

EtherNet/IP is one of the open network standards, like DeviceNet and ControlNet. It is an industrial application layer protocol for industrial automation applications. Ethernet/IP uses all of the protocols of traditional Ethernet including the Transport Control Protocol (TCP), the Internet Protocol (IP) and the media access and signaling technologies. Building on standard Ethernet technologies means that Ethernet/IP will work transparently with all the standard Ethernet devices found today. EtherNet/IP application layer is based on the ˇ§Common Industrial Protocolˇ¨ (CIP) which is used in both DeviceNet and ControlNet. This standard organizes networked devices as a collection of objects. It defines the access, behavior and extensions, which allow vastly different devices to be accessed using a common protocol. Building on these protocols, Ethernet/IP provides a seam-less integrated system from the Industrial floor to the enterprise network.

Ethernet/IP uses all the transport and control protocols of standard Ethernet including the Transport Control Protocol (TCP), the User Datagram Protocol (UDP), the Internet Protocol (IP) and the media access and signaling technologies found in off-the-shelf Ethernet technology. Building on these standard communication technologies means that Ethernet/IP works transparently with all the standard Ethernet devices found in today's market-place.

|