|

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

| |

The ICP DAS WinPAC-5000 Series is the new generation PAC (Programmable Automation Controller). It is equipped a PXA270 CPU (520 MHz) running a Windows CE.NET 5.0 operating system, various connectivity (VGA, USB, Ethernet, RS-232/485) and I/O expansion bus.

The WinPAC-5000 series has many advantages, including hard real-time capability, small core size, fast boot speed, interrupt handling at a deeper level, achievable deterministic control and low cost. Using Windows CE.NET 5.0 gives it the ability to run PC-based control software such as Visual Basic.NET, Visual C#, Embedded Visual C++, SCADA software, SoftPLC ¡Ketc. It give users all of the best features of both traditional PLCs and Windows capable PCs.

For hardware expansion, it also supports an I/O expansion bus. The I/O expansion bus can be used to implement various I/O functions such as D/I, D/O,A/ D, D/A, Timer/Counter, UART, and other I/O functions. Nearly all kinds of I/O functions can be implemented by this bus. But the bus can support only one board. There are more than 10 boards available for WinPAC-5000 series, users can choose one of them to expand hardware features. |

|

| |

|

|

|

|

|

| |

back |

|

| |

|

|

| |

|

|

| |

|

|

| |

|

- Supports PC based software: eVC and VS .NET 2005/2008

- Web server, FTP server, Telnet server

- ISaGRAF version for IEC 61131-3 programming

- InduSoft version for SCADA solution

|

|

|

| |

|

|

| |

2. Local I/O and Communication Expansion Board

WinPAC-5000 series equip an I/O expansion bus to support one optional expansion board, called XW-board. It can be used to implement various I/O functions such as DI, DO, A/D, D/A, Timer/Counter and various communication interface, such as RS-232/422/485, CAN, FRnet, etc. |

|

|

|

| |

|

|

| |

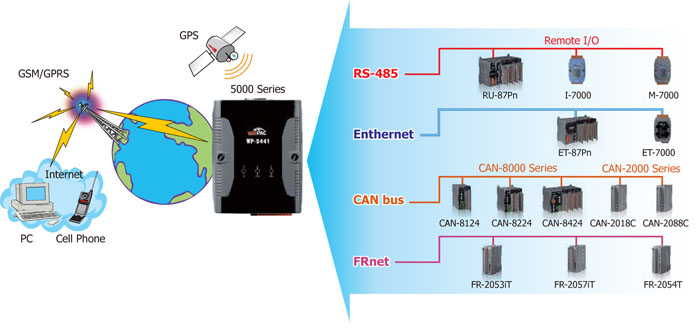

3. Remote I/O Module and Expansion Unit

With the built-in RS-485 and Ethernet port, the 5000 series can connect RS-485/Ethernet remote I/O units (RU-87Pn/ET-87Pn) or modules (I-7000/M-7000/ET-7000). With an XW-board, the 5000 series can have more communication ports or different interface to connect to other type of devices, for example: CANOpen devices, DeviceNet devices, or FRnet I/O modules. |

|

4. Multi-Communication Interface

There are serval of communication interfaces to expand I/O and connect to external devices: |

1. Ethernet

2. RS-232/485

3. USB host

4. CAN bus |

5. FRnet

6. GPS

7. GSM/GPRS |

|

|

| |

|

|

| |

|

|

| |

5. Various Memory Expansions

WinPAC-5000 provides various memory storage options, such as EEPROM and microSD. Customers can choose the memory based on their characteristics. |

- 16 KB EEPROM: to store not frequently changed parameters.

- microSD/microSDHC: to implement portable data logging applications.

|

|

|

|

| |

|

|

| |

|

6. Unique 64-bit Hardware Serial Number to Protect Your Program

A unique 64-bit serial number is assigned to each hardware device to protect your software against piracy. |

|

|

| |

|

|

| |

7. Small and Easy Installation

WinPAC-5000 series have a palm-size shape (91 mm x 132 mm x 52 mm)

to be installed in a narrow space with DIN-Rail. |

|

8. Plastic and Metal Casing

The default case is plastic material, customers can choose metal case if they want. |

|

|

| |

|

|

| |

| 9. Highly Reliable Under Harsh Environmen |

|

Our £gPACs operate in a wide range of temperature and humidity.

- Operating Temperature: -25 ~ +75 ¢XC

- Storage Temperature: -30 ~ +80 ¢XC

- Humidity 10 ~ 90% RH (non-condensing)

|

|

|

| |

|

|

|

|

|

| |

back |

|

| |

|

|

|