Smart Factory

Introduction

ICP DAS has the advantage of a rich experience in the management of water resources, the collection of electricity consumption information, as well as the monitoring of compressed gas, toxic gas, gas, lighting, air conditioning, fire prevention procedures, and access control integration, meaning that we are able to provide our customers with the most appropriate recommendations for integration.

Why ICP DAS

Applications

Machine automation technology enables the whole spectrum of applications, playing a vital role in the global manufacturing industry. Automated production lines significantly assist manufacturers in remaining competitive in the dynamic market and meeting customer-specific requirements. Motion control, a crucial machine automation technology, continuously advances and improves. The higher precision and speed achieved further fuel the development of collaborative robots and control systems.

ICP DAS provides a wide range of motion solutions for machine automation systems, including PC-based solutions, embedded PAC solutions and remote motion solutions using Ethernet, Serial Communication, Motionnet, EtherCAT or CANopen motion control products for distributed motion control systems.

ICP DAS One-stop EtherCAT Services Answer the Call for High-performance Solutions

ICP DAS provides customers with one-stop EtherCAT shopping services. A comprehensive range of products includes master boards, motion controllers (EtherCAT master), and dozens of slave devices, offering compatibility with various brands. The master devices have the capability to update multiple slave devices in real time, with a cycle time of up to one millisecond...

As the present issues involved in industrial safety are closely related to personal safety, they often result from a top-down policy to prevent personal injury and disaster caused by the improper use of equipment, or the problems associated with the equipment itself, including:

- The adoption of an electricity consumption safety monitoring system for the distribution board (electromechanical control panel) that is able to prevent fires caused by the short circuiting or smoldering of wires.

- Whether or not there is toxic gas detection, personnel dumping detection, personnel positioning detection, or more in a hazardous work area, except for special operational procedures.

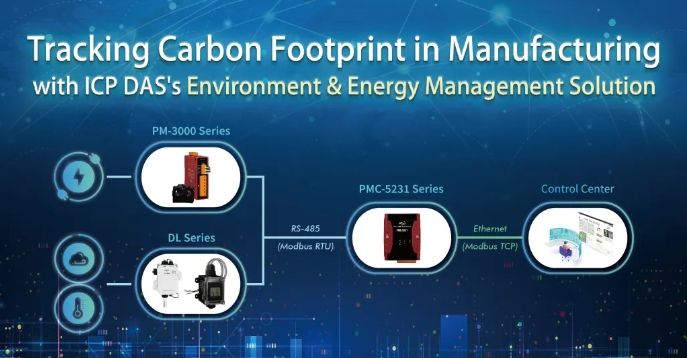

ICP DAS’s Intelligent Cooling Tower Status Monitoring: Precisely Capture Every Data Point

ICP DAS’s I-87K series I/O modules capture analog data from the cooling tower, including cold and hot water temperatures, wet-bulb temperature, outlet pressure, hydrostatic level, and motor current of the cooling fan. The PET series PoE Ethernet high-speed data acquisition modules receive vibration data from accelerometers monitoring the cooling fan system.This data is transmitted via the Modbus TCP...

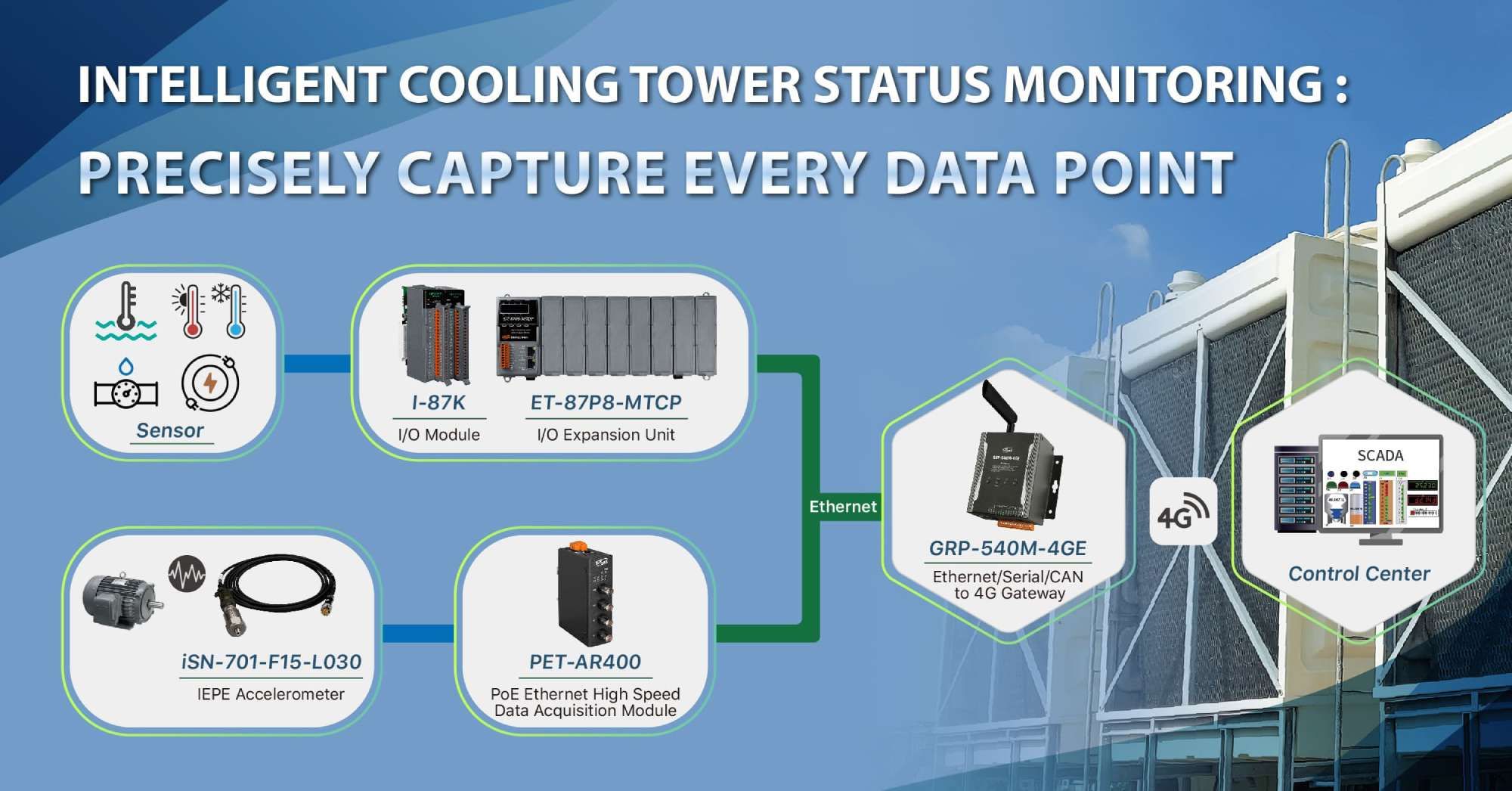

Minimizing Hazardous Leaks in Vast Oil Refinery with ICP DAS ZigBee Wireless Solution

ICP DAS provides a gas leak detection solution, enabling monitoring and control of gas concentrations in oil refineries — no matter how large the plants are — through the wireless network. ICP DAS ZT-2017C ZigBee Current Input Module converts 4-20mA analog current signals into readable digital values and transmits the data to the ZT-2510 ZigBee Repeater via ZigBee wireless communication...

As the scope for environmental monitoring is quite broad, the easiest way for smart factories to achieve this is to introduce an environmental monitoring system, which is applicable to all industries, and is used to prevent potential environmental disasters and hazards to personnel, thereby improving the comfortable usage of space, and reducing the risk of property loss.

- Emergency button systems and lighting systems mostly present in public spaces

- Monitoring of parameters such as temperature and humidity, air quality, air conditioning, ventilation, water leakage conditions for production lines and storage areas

- Factory patrol system

- Access control and monitoring of laboratory and facility rooms.

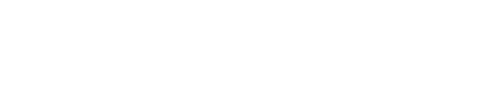

Tracking Carbon Footprint in Manufacturing with ICP DAS’s Environment and Energy Management Solution

Users can collect information about the electricity consumption of factories and equipment with the ICP DAS‘s three-phase smart power meter PM-3000 series and the IIoT power meter concentrator PMC-5231. The smart power meter and power meter concentrator can also be used in conjunction with ICP DAS‘s air sensor modules to obtain temperature, humidity, and PM concentration data...

Application Case of Cold Storage Warehouse Temperature Monitoring in a Beverage Plant

To implement remote temperature monitoring of the cold storage warehouse, the client used a WISE series IIoT edge controller and remote I/O modules from ICP DAS to convert and transmit the current temperature sensor data to the control center in real-time. Collecting...

The application of ICP DAS’ s solution for leakage monitoring and access control in cleanrooms

To By using the ICP DAS’s environmental monitoring modules with the WISE IIoT edge controller, leak, temperature, humidity, and access control information can be easily sent to the control center for remote monitoring and strict control of environmental conditions in the cleanroom...

- Product stability, reliability, and trustworthiness are some of the most important factors that must be considered by the machine equipment manufacturing industry, which is mainly due to the extended introductory phase required for the test equipment, as well as the application phase. ICP DAS not only excels by providing one of the most complete range of I/O and motion control modules when compared to its competitors within the same industry, but also offers ODM services based on the needs of our customers, helping to perfectly integrate our recommendations into the existing framework.

- ICP DAS has sufficient practical experience and the most complete product lines, meaning that we can assist company proprietors in integrating the monitoring of their equipment status, as well as calculating the possibility for them to initiate the start of data visualization by introducing a three-color stack light monitoring module and equipment networking.

ICP DAS Offers Integrated Automation Solution for FOUP Stocker Systems in Semiconductor Manufacturing

The customer uses ICP DAS’s CAN-205XD series DeviceNet remote I/O slave module and the AXP-9051-IoT programmable automation controller (PAC) to assist the O-brand PLC to drive various mechanisms in the FOUP (Front Opening Universal Pod) stocker, creating a fully automated FOUP stocker system...

Optimizing Semiconductor Storage Conditions: T&H Monitoring with ICP DAS ZigBee Wireless Solution

ICP DAS’s DL-100 Series T&H Data Loggers, along with ZT Series ZigBee Wireless Converters, collect and transmit real-time data on warehouse temperature and humidity to the AVEVA Edge SCADA in the control center for remote monitoring. When temperature and humidity values are abnormal, the system triggers alarm, allowing managers to...

Factory Upgrade & Networking Project to Optimize Passive Component Production

The customer uses the M-7026-G Multi-function I/O Module and M-7018R-G Thermocouple Input Module to collect machine data such as temperature and status. The collected data is then sent to the MDC-700 Series – Modbus Data Concentrator first, facilitating efficient data transmission to the AVEVA Edge HMI & SCADA Software...

ICP DAS’s Wireless Monitoring Solution for Overhead Cranes in Bicycle Painting Production Lines

Using ICP DAS's M-7000 series I/O modules and RFU series wireless modem, customers can bridge the communication between overhead cranes and PLCs on the ground through the radio frequency (RF) to control overhead cranes in bicycle painting production lines remotely...

ZigBee Application – Route Management System for AGV

In recent years, unmanned factory or warehouse automation systems has become popular. Automatic Guided Vehicles (AGV) are used to transport goods to and from the product lines, storage systems, and transfer stations, etc. If there are several AGVs in the same location, vehicle driving routes may overlap. Consequently, preventing route conflict is an important issue...

ICP DAS’s Machine Data Visualization Solution for Monitoring Aluminum Wheel Production in India

The iKAN-116S small-sized industrial LED display and the GW-7663 PROFINET to Modbus TCP gateway module provided by ICP DAS can be used to read and display the machine status from the PLC, so that the...

.jpg)