iWSN Series (Industrial Wireless Sensor Network)

Semiconductor, electronics manufacturing

With the trend toward smart manufacturing and flexible manufacturing, the production process is becoming increasingly complicated, and each production stage is interlocked. The condition of the equipment is evaluated using the concept of predictive maintenance to maintain the operation of the production line. In response to the Internet of Things (IoT), big data analysis, Industry 4.0, energy -saving and carbon -reduction requirements, ICPDAS has developed the "Industrial Wireless Sensor Network" solution. In addition to integrating current, temperature measurement, and wireless transmission functions into a single module, the ultralow power consumption can be matched with a current transformer (CT) for inductive charging, it can meet the supply and demand balance of working power and supply the required continuous uninterrupted measurement equipment parameters with sufficient power. The settings can be completed using a DIP switch, which not only doesn't affect the production process, but also greatly saves system construction time and reduces maintenance costs. To meet the power consumption needs of monitoring equipment, predictive maintenance and power panel temperature monitoring, it's helpful to maintain the production line equipment and prevent accidents caused by the aging of power panel equipment and cables.Comparison between Traditional and iWSN methods

| Item | Traditional Meter | iWSN Series |

|---|---|---|

| Main function | Measuring power parameter data | Measuring current, temperature and DI (Continuous development of vibration, gas detection, etc.) |

| Accuracy | <1% | <3% or ±0.3A |

| Cycle | At least once per second | 1/10/30/60 seconds |

| Power | DC power provides an additional transformer | CT charging, battery storage (Easy to install and maintain, and easy to build) |

| AC power provides power lines | ||

| Power configuration | 100% (7W)(Wireless Module + Meter + Power Supply) | 0.3% (20mW) Power saving design |

| Parameter setting | Software Utility | DIP switch setting |

| Hardware cost | General | Low |

| System defect | Long construction time, system needs to be powered off to be built, complicated to set up, and difficult to maintain | Easy functions, low data update speed |

| Application | Monitoring system, electricity billing, energy efficiency actuarial or power quality analysis | Big data analysis, system monitoring, trend analysis and predictive maintenance |

Features

-

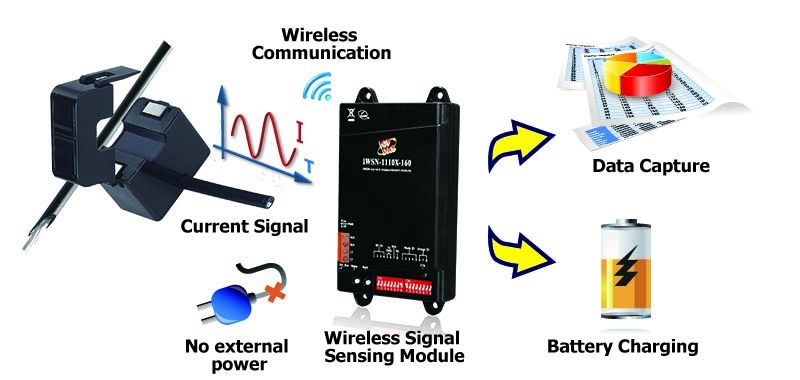

Wireless Sensing

The iWSN wireless signal sensing module is fastened to the circuit being measured wire via the CT. The CT is usually in charging mode and can store the current received from the charging circuit in the battery. When the charging energy is greater than or equal to the power consumption, the wireless sensing module can operate continuously. If it is necessary to measure the current information from the power line, the module will automatically switch to operating mode to introduce the current signal into the circuit being measured. The result and state parameters for the module will be transmitted to the iWSN concentrator via wireless communication, and then the module will switch back to the charging state until the next measurement.

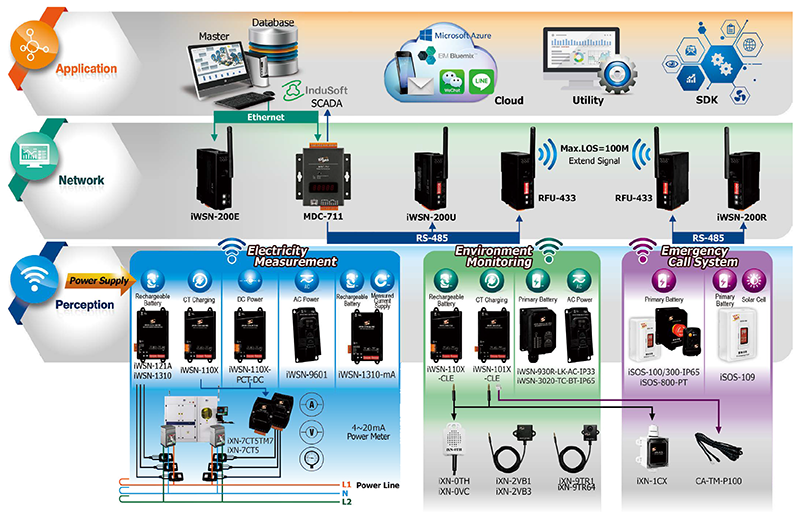

System Structure

The iWSN network system includes a wireless data concentrator and a wireless sensing module. If there are more signal points to be collected, the IO interface on the iWSN I/O expansion module can be used to connect to these devices. The information collected by the iWSN data concentrator can be used to provide information to the field personnel through the ICP DAS touch panel controller, or the data can be sent to the cloud via a WISE series IIOT smart controller, or even connecting to instant messaging software. For the connection between the field communication network and the backbone of the network, ICP DAS also provides a series of converters, allowing data to be instantly uploaded to the control center for subsequent big data analysis

Wireless Data Concentrator

iWSN-200 series collect and return the data from the sensor, provide Modbus RTU or Modbus TCP standard communication protocol to connect with upper system or graphics control software.|

|

||||||||

|

iWSN wireless data concentrator

|

||||||||

| Model | Frequency | Interface | Protocol | Baud Rate | DO | Certification | ||

|---|---|---|---|---|---|---|---|---|

| Channel | Type | Rating | CE RED | |||||

| iWSN-200U

|

433MHz | RS-232 or RS-485 x 1 | Modbus RTU | 1200 to 115200 bps, N81 |

- | Yes | ||

| iWSN-200R

|

RS-485 x 1 | 1 | Power Relay, From A (SPST N.O) |

5A | - | |||

| iWSN-200E

|

Ethernet x 1 | Modbus TCP | 10/100 Mbps | - | - | |||

Wireless Signal Sensing Module

In addition to the energy acquisition by the connected CT (Current Transformer), current value of the cable on CT is also measured and transmitted back to the data concentrator via wireless. Depending on model, channels or expansion interface such as split-core type CT, Rogowski coil, temperature, and DI dry contact are available.

|

|

||||||||||||

|

Wireless Signal Sensing Module

|

||||||||||||

| Module Name | Split-Core CT specifications | Thermistor (Optional) | DI specification | AI specification | Other | Certification | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CT Channel | CT Type | Rogowski Coil Channel | Rogowski Coil Type | Channel | Measurement Range | Channel | Type | Channel | Current Input | Expansion interface (Support iXN-7CT5 series) | CE RED | |

| iWSN-110X-PCT-DC | 1 | Φ16mm (100A), Φ24mm (200A) and Φ36mm (400A), 8m (Note 1) | - | - | - | - | - | - | - | - | Yes | - |

| iWSN-110X-PCT-ME | 1 | - | - | - | - | - | - | - | - | Yes | Yes | |

| iWSN-110X-160-ME | ||||||||||||

| iWSN-110X-240-ME | ||||||||||||

| iWSN-110X-360-ME

|

||||||||||||

| iWSN-121A-160-ME

|

2 | 1 | 0 °C ~ 80 °C | 1 | Dry contact | - | - | - | - | |||

| iWSN-121A-240-ME

|

||||||||||||

| iWSN-121A-360-ME

|

||||||||||||

| iWSN-1310-160-ME

|

3 | 1 | 0 °C ~ 80 °C | - | - | - | - | - | ||||

| iWSN-1310-240-ME

|

||||||||||||

| iWSN-1310-360-ME

|

||||||||||||

| iWSN-1310-PCT-ME

|

||||||||||||

| iWSN-1310-mA-ME

|

- | - | - | - | - | - | - | - | 3 (Differential) |

0 ~ 20 mA | - | |

| iWSN-110X-RCT1000P-CT

|

1 (For charging only) | Φ24mm (200A) | 1 | Φ80mm (1000A), 4m | - | - | - | - | Yes | Yes | ||

| iWSN-110X-RCT1000PL-CT

|

Φ36mm(400A) | |||||||||||

| Note 1:The accessories of iWSN-1□□□-160-ME, iWSN-1□□□-240-ME and iWSN-1□□□-360-ME are Φ16mm (100A), Φ24mm (200A), and Φ36mm (400A) separately. | ||||||||||||

Wireless Power Meter Module

The voltage signal inputs are not only for calculating the energy information, but also for the working power of the modules. By using the wireless communication interface, the energy information is easy transmitted to the data concentrator. Users can have different CT types, dimensions and measurement range by selecting the different model number as below.|

|

|||||||||

|

Multi-circuit Wireless Power Meter

|

|||||||||

| Model | Phase | Loop | Bi-dir. Energy (Note 2) |

CT Included |

Max. Voltage |

Max. Current |

Max. CT ID |

Cable Length |

CE RED |

|---|---|---|---|---|---|---|---|---|---|

| iWSN-9601-PCT-ME-IP33 | Single | 6 | Yes | - | 277V | 400A | 36mm | 8m | - |

| iWSN-9601-160-ME-IP33 | Yes | 100A | 16mm | ||||||

| iWSN-9601-240-ME-IP33 | 200A | 24mm | |||||||

| iWSN-9601-360-ME-IP33 | 400A | 36mm | |||||||

| iWSN-9603-PCT-ME-IP33 | Single/ Three |

4/2 | Yes | - | 277V | 400A | 36mm | 8m | Yes |

| iWSN-9603-160-ME-IP33 | Yes | 100 A | 16 mm | ||||||

| iWSN-9603-240-ME-IP33 | 200 A | 24 mm | |||||||

| iWSN-9603-360-ME-IP33 | 400 A | 36 mm | |||||||

| iWSN-9603-RCT500P-ME-IP33 | 500 A | 55 mm | 4m | ||||||

| iWSN-9603-RCT1000P-ME-IP33 | 1000 A | 85 mm | |||||||

| iWSN-9603-RCT2000P-ME-IP33 | 2000A | 105mm | |||||||

| Note 1: The model names with -RCTxxxP- are for Rogowski coil CT, the others are for the split coil CT. Note 2: [Bi-dir. Engergy] stands for [Bi-directional Energy]. |

|||||||||

I/O expansion module

Expandable CT and temperature measurement interface. iXN-7CT5 series connect to the sensing module by wireless, and transmit the value which is collected by expansion module to sensing module, further to data concentrator.|

|

|||||

|

iXN Expansion Sensing Module

|

|||||

| Model | Split-core CT Channel Number | Split-core CT Error | Thermistor Channel Number | Temperature Error | |

|---|---|---|---|---|---|

| iXN-7CT5

|

5 | <3% or 0.3A | - | - | |

| iXN-7CT5TM7

|

7 | < 2 °C | |||