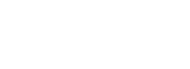

Overall Equipment Effectiveness Application

A SCADA system is commonly used in a factory control room to collect field data,

such as the temperature, flow, pressure, and vibration. When an iKAN device is installed in the field,

it can display information from the SCADA system to help the operators quickly obtain detailed information about the operating status of the device.

This also raises the effectiveness of the real-time management performance for the devices, thereby extending the lifetime of the device.

Furthermore, if the system suffers a malfunction, the iKAN device can be used to display information about the failure together with any repair instructions, which can shorten the repair time and reduce any losses caused if the production line must be stopped.

Factory Energy Management Application

The iKAN device can display either real-time or historical data related to the chiller liquid flow,

chilled water temperature, and power consumption, etc., which is then acquired and analyzed using SCADA software.

This helps the engineers to identify the current performance and power consumption of the chiller, which can help in determining a suitable time for maintenance on the chiller.

Any abnormal data can also be displayed on the iKAN device to inform the engineers of any problems, preventing any loss due to power overloading.

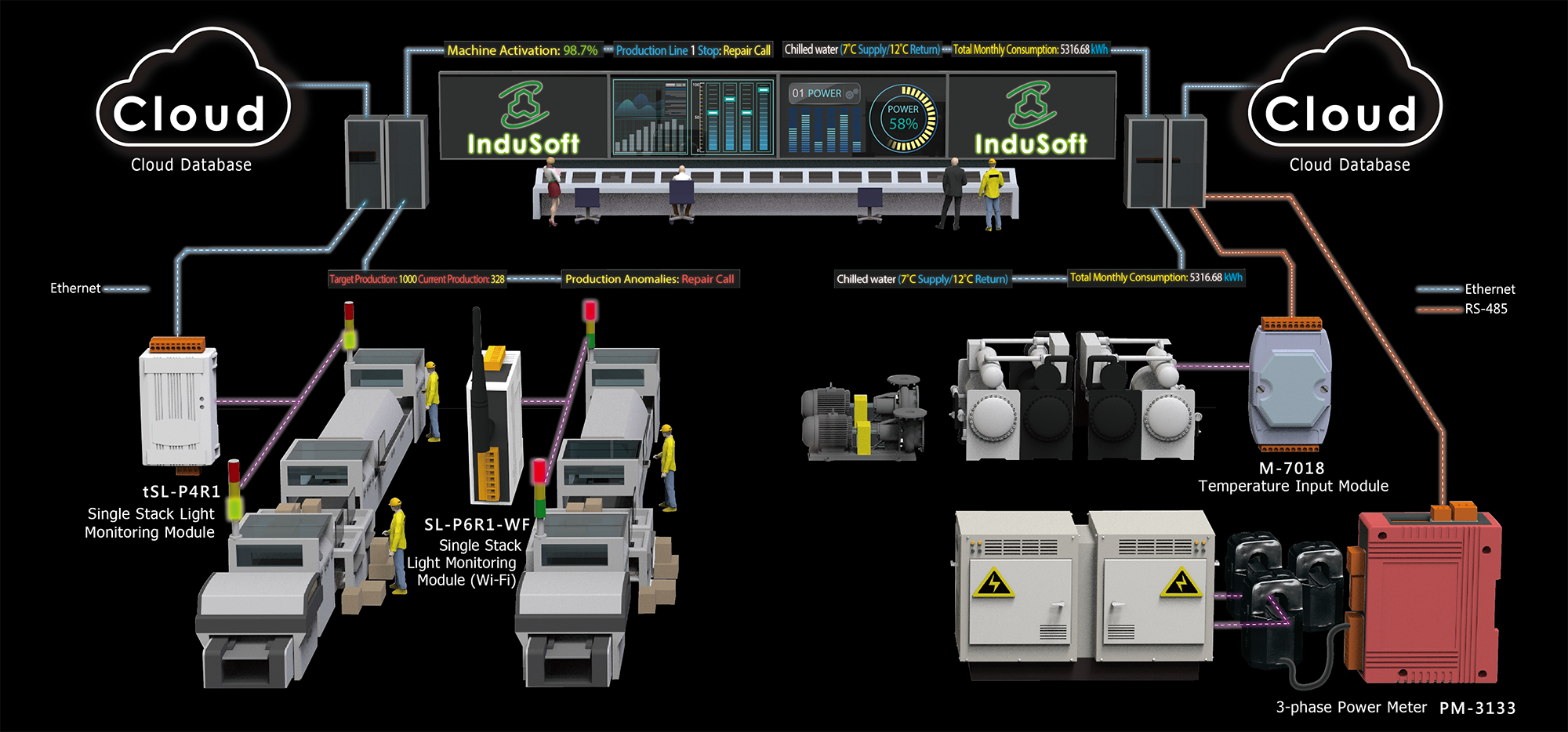

Air Quality Monitoring

The iKAN device can obtain and display data from ICP DAS DL sensor modules, including details of the CO, CO2, and PM2.5 levels, the temperature, and the humidity, etc., without requiring any programming skills or knowledge, meaning that the operators will know how to handle any issues when environmental conditions are abnormal.

System Structure

Copyrights © 2019 ICP DAS CO., LTD. All Rights Reserved.