Introduction

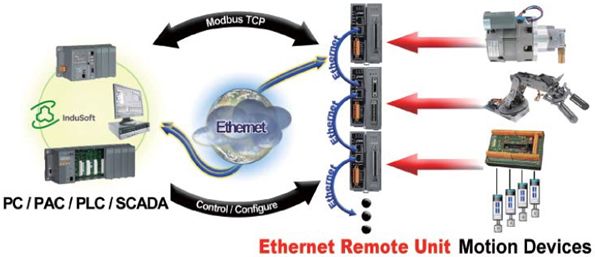

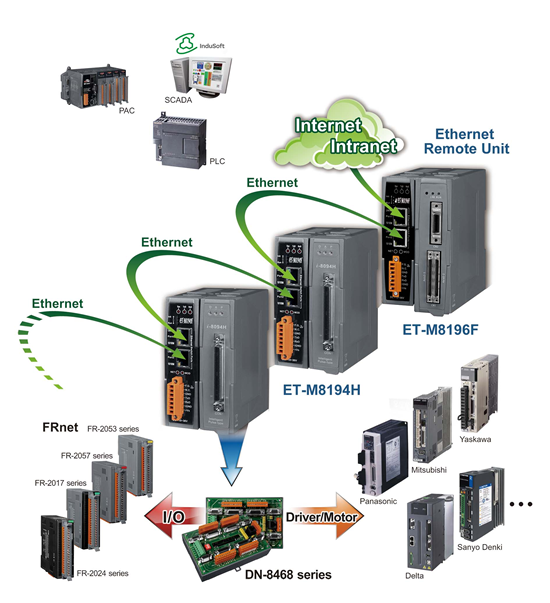

ICP DAS remote Ethernet motion control series consist of a four axis (ET-M8194H) and a six axis (ET-M8196F) stepping/pulse-type servo motion controller. Each motion control device is equipped with an Ethernet communication module and uses Modbus TCP/IP as its communication protocol. In a Modbus TCP network the ET-M8194H/ET-M8196F acts as a server. All standard Modbus function codes are supported and therefore any Modbus TCP master (e.g. PC, PLC, HMI, PAC, etc.) can access the remote motion controller. Each device is equipped with two Ethernet ports which allow daisy chain Ethernet wiring; multiple devices can be connected together in sequence without an additional Ethernet switch. This intelligent motion controller has a variety of built in motion control functions, such as multi-axis linear interpolation, circular interpolation, T/S-curve acceleration/deceleration, various synchronous actions and automatic homing. A software utility assists the user in configuring the Ethernet module and motion card and provides some basic motion commands for testing. An application programming interface (API) allows the programmer to develop an application program to remotely control the motion device.

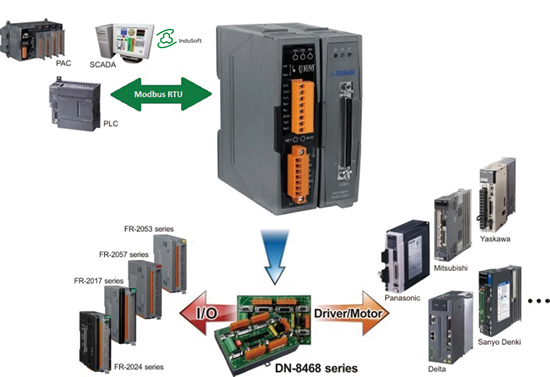

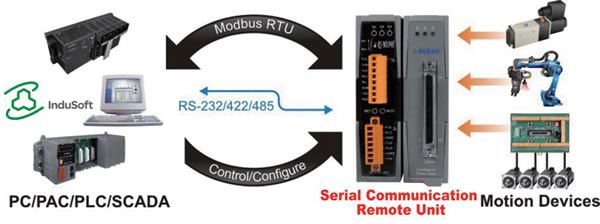

ICP DAS provides two types of remote serial motion controller: 4 and 6 axes stepping/pulse-type motion controller. Both controller types support RS232, RS485 and RS422 serial communication and uses Modbus RTU as a communication protocol.

Serial communication speed can be set by selecting a standard baud rate. The remote controllers are defined as a Modbus slave. The standard Modbus functions are supported which enables the user to easily integrate the motion controller into an existing Modbus network. PC, HMI, PAC, PLC and other devices which support Modbus RTU can access, control and monitor the motion controller.

Software utilities are provides which allows the user to configure the device and execute simple motion commands for testing purposes. Windows APIs for developing motion control application are included in the software package.

|

|

|||||||||||||

|

Remote Motion Control Unit

|

|||||||||||||

| Model | No. of Axes | Protocol | Encoder Input | Pulse Output | FRnet | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Counter Width | Counting Rate | Mode | Counter Width | Mode | Rate | ||||||||

| ET-M8194A | 4 | Ethernet (Modbus TCP) | 32-bit | 4 MHz | A/B Pulse, Up/Down | 32-bit | CW/CCW, PULSE/DIR | 4 MPPS (Max.) | - | ||||

| ET-M8194H

|

Yes | ||||||||||||

| ET-M8196F

|

6 | 12 MHz | CW/CCW, PULSE/DIR, A/B Pulse | ||||||||||

| RS-M8194H

|

4 | RS-232/422/485 (Modbus RTU) | 4 MHz | CW/CCW, PULSE/DIR | |||||||||

| RS-M8196F

|

6 | 12 MHz | CW/CCW, PULSE/DIR, A/B Pulse | ||||||||||

Application Notes:

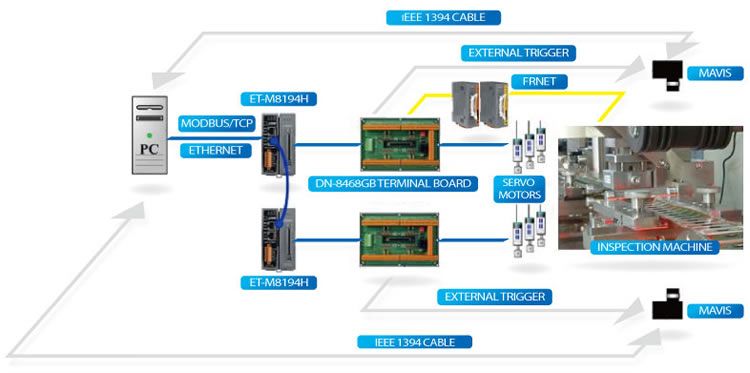

In a recent case, ET-M8194H units were installed on machines performing IC inspection. Each machine was equipped with two ET-M8194H modules to coordinate six motors by taking advantage of the embedded Ethernet switching ports on the ET-M8194H. Therefore six axes motion control could be easily implemented by connecting two ET-M8194H modules in series (daisy-chain topology). The supervisory host PC was used to issue commands and collect information through the Ethernet without the need for additional wiring. The application can also be accomplished by using the ET-M8196F.

ET-M8194H Application Structure and Features:

- Compact Size

- Easy to Use

- Stand-alone

- Supports the Modbus TCP protocol

- Easy integration into a SCADA, PAC or PLC Modbus TCP network

- The device can be set as a remote or stand-alone motion controller

- ET-M8194H supports 4-axis motion control: 2/3-axis linear interpolation, etc.

- ET-M8196F supports 6-axis motion control: 2- To 6-axis Linear/2- To 3-axis Circular Interpolation, etc.

- Supports high-speed FRnet I/O: 128 digital outputs and 128 digital inputs

- Supports macro programming

- Includes the EzMove utility for system configuration and macro program editing

- Supports FRnet DI or event triggered macro program execution

- Supports IP blocking

Application Notes:

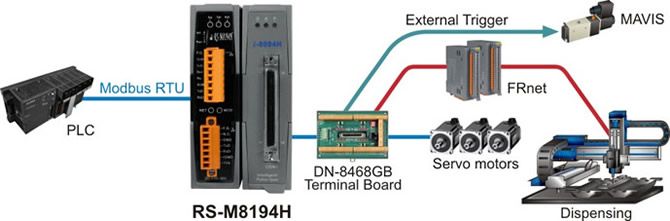

In a recent case, a PLC together with a RS-M8194H was used to control the dispensing path of an automated dispensing system. With the three-axis interpolation function provided by RS-M8194H it was possible to move two dispensing nozzles synchronous along predefined curves with varying velocities. It was a requirement to change the velocity on the fly in order to ensure a set dispensing thickness along the motion path.

Application Structure and Features:

- Compact Size

- Easy to Use

- Stand-alone

- Supports the Modbus RTU protocol

- Easy integration into a SCADA, PAC or PLC Modbus RTU network

- The device can be set as a remote or stand-alone motion controller

- RS-M8194H supports 4-axis motion control: 2/3-axis linear interpolation, etc.

- RS-M8196F supports 6-axis motion control: 2- to 6-axis linear/2- to 3-axis circular interpolation, etc.

- Supports high-speed FRnet I/O: 128 digital outputs and 128 digital inputs

- Supports macro programming (for RS-M8194H only)

- Includes the EzMove utility for system configuration and macro program editing (for RS-M8194H only)

- Supports FRnet DI or event triggered macro program execution (for RS-M8194H only)