PCC-1416

Introduction

- Easy-to-use

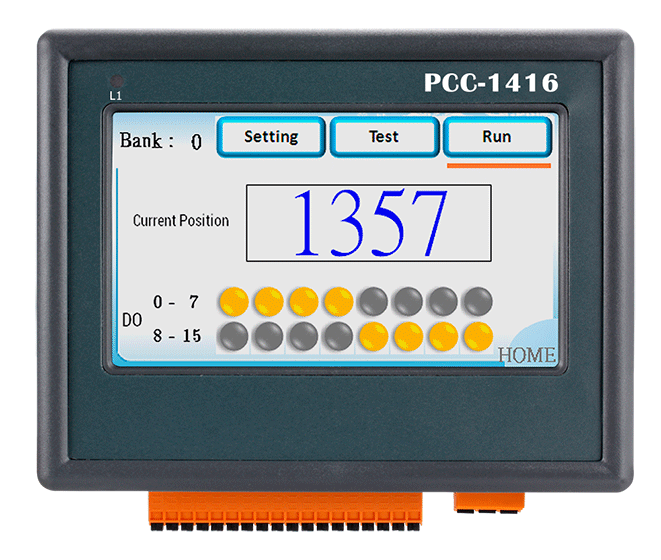

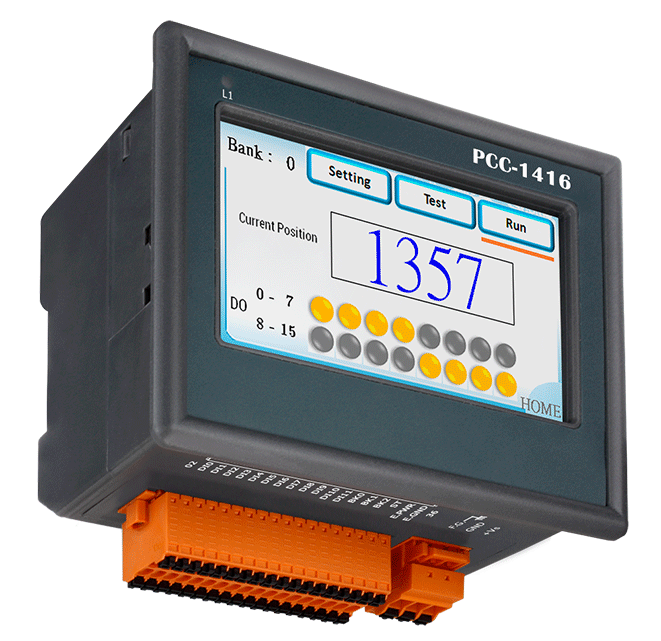

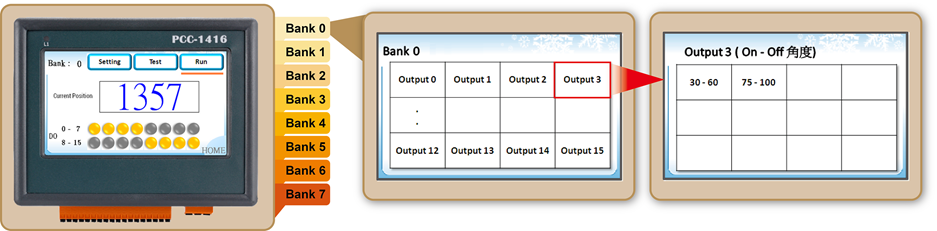

The controller is equipped with a 4.3-inch high-resolution color TFT touchscreen, providing an intuitive and convenient operation interface, significantly simplifying the setting process. Each operation page is divided by function, and only necessary information is displayed to avoid excessive complexity, making parameter settings more intuitive and easy to understand. The virtual numeric keypad allows for quick input of angle and position values, enhancing operational convenience. Users can easily duplicate Bank and Output parameters, simplifying the repetitive setup process.

-

High Resolution Encoder Input

PCC-1416 supports Binary Code and Gray Code and can be used with absolute encoders. Its resolution can reach up to 12 bits (4096 or 0.08°), enabling finer and more stable operation, ensuring that the product meets stringent specifications, and significantly enhancing quality and consistency

-

8 Banks, 16 Outputs, and 32 Areas

The controller provides 8 banks (program), each of which can support up to 32 area settings. Each area setting allows for the configuration of ON/OFF angle or position parameters and can be assigned to one CAM output channel. Users can quickly switch to the bank based on different production needs, enabling multi-functionality and enhancing the flexibility and efficiency of the production line.

- Output Protection and Emergency Stop

PCC-1416 provides a Start Input pin, which must be grounded before allowing the module's DO (CAM) channels to output, to prevent abnormal output during machine testing and adjustment. It can also as an emergency stop switch, enabling on-site personnel to quickly control the system and reduce workplace safety risks.

- Teaching Mode

In addition to manually entering the angle or position value, you can also directly use the encoder current value. The teaching mode is integrated into the operation process, allowing the controller to automatically update the values without needing to switch modes.

- Password Protection and Quick Adjustment

Built-in password protection effectively prevents unauthorized users from modifying parameters. All output area parameters have been digitized without the need to replace or redesign the physical CAM. Users can be quickly switched according to needs, easily achieving diversified control.

- High Durability

Since there are no mechanical parts prone to wear as in traditional CAM systems, the electronic CAM controller offers a longer lifespan and lower maintenance requirements. The front panel ensures the reliability of the controller in harsh environments.

Applications

- Application of CAM Controller in Turret Test Machine

Ordering Information

| PRODUCT SERIES | DESCRIPTION | QNT. | INQUIRY |

|---|---|---|---|

Similar Products

| Display | |

|---|---|

| Type | TFT LCD (65535 colors), defective pixels <= 3 |

| Size | 4.3" |

| Backlight Life | 20,000 hours |

| Brightness | 400 cd/m2 |

| Resolution | 480 x 272 |

| Touch Panel | Yes |

| LED Indicators | |

|---|---|

| Status | 1 |

| Encoder Input | |

|---|---|

| No. of Axes | 1 |

| Mode | CW/CCW (Programmable) |

| Coding Format | Binary/Gray Code |

| Resolution | 12-bit (Max.) |

| Pulses Per Revolution | 360/720/2048/4096 |

| Frequency | 1200 rpm @ 360 PPR 600 rpm @ 720 PPR 210 rpm @ 2048 PPR 105 rpm @ 4096 PPR |

| Digital Input | |

|---|---|

| Channels | 1x Start Input 3x Bank Input |

| Type | Wet |

| Sink/Source (NPN/PNP) | Sink (NPN) |

| ON Voltage Level | + 3 VDC (Max.) |

| OFF Voltage Level | + 10 ~ 24 VDC |

| Digital Output | |

|---|---|

| Channels | 16 |

| Type | Open Collector |

| Sink/Source (NPN/PNP) | Sink (NPN) |

| Load Voltage | + 30VDC (Max.) |

| Load Current | 100 mA (per channel) |

| Response Speed | 150 μs (Max.) |

| HMI | |

|---|---|

| Buzzer | Yes |

| Rotary Switch | 0 ~ 9 |

| Reset Button | Yes |

| USB | |

|---|---|

| Ports | 1x USB 3.1 (Firmware updates only) |

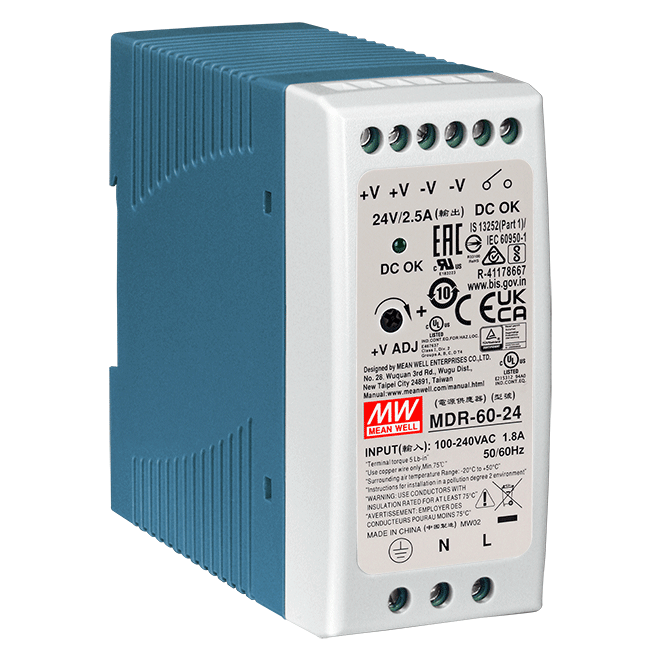

| Power | |

|---|---|

| Input Range | + 12 ~ 48 VDC |

| Consumption | 2.5 W |

| Mechanical | |

|---|---|

| Dimensions (mm) | 131 x 114 x 54 |

| Panel Cut-out (mm) | 120±1, 92±1 |

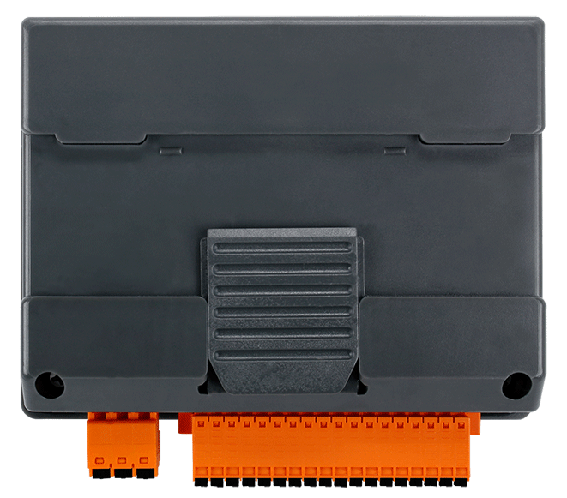

| Installation | DIN-Rail mounting / Wall mounting |

| Ingress Protection Rating | Front panel: IP65 |

| Environment | |

|---|---|

| Operating Temperature | -20 ~ +50°C |

| Storage Temperature | -30 ~ +80 °C |

| Humidity | 10 ~ 90% RH, Non-condensing |