Automation Taipei 2023

Exhibition

Taipei Nangang Exhibition Center, Hall 1, 4F, Booth L1028,Taiwan

- Description

- Highlights

Exhibition Information

Automation Taipei 2023

Date:2023/08/23 (Wednesday) – 08/26 (Saturday)

Time:9:30 AM ~ 5:00 PM (Closed at 4:00 PM on the last day)

Venue:Taipei Nangang Exhibition Center, Hall 1, 4F

Booth:L1028

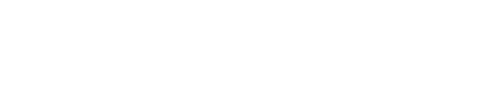

Complete the registration form for admission.

>> Apply Now

Admission

For safety reasons, children under the age of 12 will not be admitted.

Registration is required for each visitor as the admission QR Code cannot be shared.

【Online-registration】

Exhibit Highlights

- Cloud-based Air Quality Monitoring & Data Visualization

- IoTstar - IoT Cloud Management Software for Equipment Monitoring

- Energy Management Solution

- Intelligent Predictive Diagnostics & Preventive Maintenance

- EtherCAT Solution

- OPC UA / MQTT Solution

| Location | |

| Address 1: | No.1, Jingmao 2nd Rd., Nangang District, Taipei City 11568, Taiwan |

|---|---|

| Country: | Taiwan |

| Event Location: | Taipei Nangang Exhibition Center, Hall 1, 4F, Booth L1028 |

Exhibit Highlights

Cloud-based Air Quality Monitoring & Data Visualization

In an industrial environment, hydrogen sulfide (H₂S) present poses a threat to factory workers and can lead to unavoidable health risks. Businesses may face punishments and fines if an occupational hazard arises. Installing ICP DAS "WISE-5231 + DL-1000 series" on site enables real-time detection of H₂S concentrations. The data is then sent to the back-end management center. WISE, with pre-configured IF-THEN-ELSE rule settings, automatically takes corresponding actions based on the detected gas concentration. Besides, alarm notifications are sent to the right personnel to prevent unfortunate incidents.

IoTstar - IoT Cloud Management Software for Equipment Monitoring

IoTstar is a software developed by ICP DAS. It can be installed on a general PC platform and works as a Private IoT Cloud system or on the VM (Virtual Machine) platform and works as a Public IoT Cloud system. Using IoTstar to build an IoT Cloud system provides 5 services as follows.

Controller Remote Access/Maintenance Service:IoTstar provides cloud-based maintenance and management for controllers, including status monitoring, configuration adjustments, and firmware updates.

Sensor Data Collection and Storage:IoTstar collects data from sensors connected to controllers and imports the data to the Database in the Cloud.

Sensor Data Visualization:IoTstar Dashboard visualizes measurements from sensors connected to controllers, enabling remote monitoring and control.

Sensor Data Reports and Analysis:IoTstar provides measurement reports for data analysis.

Bidirectional Interactions via Mobile Devices:Using LINE App to query, monitor and control sensor status through the cloud.

Controller Remote Access/Maintenance Service:IoTstar provides cloud-based maintenance and management for controllers, including status monitoring, configuration adjustments, and firmware updates.

Sensor Data Collection and Storage:IoTstar collects data from sensors connected to controllers and imports the data to the Database in the Cloud.

Sensor Data Visualization:IoTstar Dashboard visualizes measurements from sensors connected to controllers, enabling remote monitoring and control.

Sensor Data Reports and Analysis:IoTstar provides measurement reports for data analysis.

Bidirectional Interactions via Mobile Devices:Using LINE App to query, monitor and control sensor status through the cloud.

Energy Management Solution

ICP DAS Energy Management Solution includes the front-end Power Meter, Power Meter Concentrator, the back-end software tool for database import operation (PMC Data Server), SCADA software, and IoTstar Cloud Management Software. Users can easily access data on energy consumption via handphones or computers while management personnel can quickly install and deploy the system, achieving energy savings.

At the small-scale phase initially, customers can effortlessly set up an energy monitoring system with ICP DAS Power Meter and Power Meter Concentrator. While scaling up, back-end software can be introduced to meet customer-specific requirements. Our solutions offer high scalability and flexibility, enabling step-by-step implementation of a variety of projects.

At the small-scale phase initially, customers can effortlessly set up an energy monitoring system with ICP DAS Power Meter and Power Meter Concentrator. While scaling up, back-end software can be introduced to meet customer-specific requirements. Our solutions offer high scalability and flexibility, enabling step-by-step implementation of a variety of projects.

Intelligent Predictive Diagnostics & Preventive Maintenance

IR Temperature Sensors

Traditionally, temperature measurement of distribution panels mainly relies on periodic manual inspections. However, a delayed inspection can lead to accidents and shutdowns. ICP DAS provides IR Temperature Imaging Solution for continuous and long-term monitoring and control of panels and raising the alarm in real time once anomalies are detected. By monitoring the temperature and power consumption of circuits and transformers in the panel, staff can assess if there is circuit aging or overload and then schedule timely maintenance and replacement.

Vibration Monitoring of Equipment

ICP DAS offers a series of vibration measurement products, including wireless, wired, and high-speed data acquisition products catering to various field equipment. In addition, they provide characteristic values for anomaly detection, fault diagnostics, and data analysis. ICP DAS "iWSN/iSN Vibration Sensor Module Series" is ideally suited for collecting data from low-frequency rotating equipment. Besides, our product series performs edge computing and features a self-powered wireless design for easy deployment and cost-effective wiring. Other series, such as "Open Controller with e-9K Vibration Data Module", "AR High-speed Vibration Data Logger Module," and "Signal Conditioning Module, Vibration Sensor with PET-7H16M," can perform data acquisition with high sampling rates.

Monitoring the Availability of Machines

The main goals of managing states of machines are to reduce downtime & production costs and increase productivity. This is easily achievable with ICP DAS Stack Light Monitor. Installing Stack Light Monitoring Module allows one to keep abreast of the process status of machines based on indicator lights. It enables the timely direction of logistical support to achieve production goals. SL-P6R1-WF/SL-PA6R1-WF and tSL-P4R1/tSL-PA4R1 can be used to monitor the MES (Manufacturing Execution System) machines, as well as detect the status of each color segment of the stack light, which can be OFF, ON, or flashing. Besides, the series provides multiple color segment combinations and reports on the past status.Through integration with SCADA, one can easily monitor the states of machines, thereby improving the availability of machines.

Tunnel Furnace/Oven Temperature Monitoring

Temperature Data Logger TCD-104 and TCD-108 feature 4-ch/8-ch K-type Thermocouples. They are powered by 4 AAA batteries and can operate for up to 60 hours. They can operate in environments up to 400°C with an additional insulation box equipped. Both are suitable for industries that require monitoring of rapid temperature changes during manufacturing, especially catering to heating curves in ovens. ICP DAS provides an iTCLoggerUtility software tool for configuring and downloading (via USB) the data from TCD-104 and TCD-108. This software can display trends and calculate static values such as maximum, minimum, and average temperatures.

Traditionally, temperature measurement of distribution panels mainly relies on periodic manual inspections. However, a delayed inspection can lead to accidents and shutdowns. ICP DAS provides IR Temperature Imaging Solution for continuous and long-term monitoring and control of panels and raising the alarm in real time once anomalies are detected. By monitoring the temperature and power consumption of circuits and transformers in the panel, staff can assess if there is circuit aging or overload and then schedule timely maintenance and replacement.

Vibration Monitoring of Equipment

ICP DAS offers a series of vibration measurement products, including wireless, wired, and high-speed data acquisition products catering to various field equipment. In addition, they provide characteristic values for anomaly detection, fault diagnostics, and data analysis. ICP DAS "iWSN/iSN Vibration Sensor Module Series" is ideally suited for collecting data from low-frequency rotating equipment. Besides, our product series performs edge computing and features a self-powered wireless design for easy deployment and cost-effective wiring. Other series, such as "Open Controller with e-9K Vibration Data Module", "AR High-speed Vibration Data Logger Module," and "Signal Conditioning Module, Vibration Sensor with PET-7H16M," can perform data acquisition with high sampling rates.

Monitoring the Availability of Machines

The main goals of managing states of machines are to reduce downtime & production costs and increase productivity. This is easily achievable with ICP DAS Stack Light Monitor. Installing Stack Light Monitoring Module allows one to keep abreast of the process status of machines based on indicator lights. It enables the timely direction of logistical support to achieve production goals. SL-P6R1-WF/SL-PA6R1-WF and tSL-P4R1/tSL-PA4R1 can be used to monitor the MES (Manufacturing Execution System) machines, as well as detect the status of each color segment of the stack light, which can be OFF, ON, or flashing. Besides, the series provides multiple color segment combinations and reports on the past status.Through integration with SCADA, one can easily monitor the states of machines, thereby improving the availability of machines.

Tunnel Furnace/Oven Temperature Monitoring

Temperature Data Logger TCD-104 and TCD-108 feature 4-ch/8-ch K-type Thermocouples. They are powered by 4 AAA batteries and can operate for up to 60 hours. They can operate in environments up to 400°C with an additional insulation box equipped. Both are suitable for industries that require monitoring of rapid temperature changes during manufacturing, especially catering to heating curves in ovens. ICP DAS provides an iTCLoggerUtility software tool for configuring and downloading (via USB) the data from TCD-104 and TCD-108. This software can display trends and calculate static values such as maximum, minimum, and average temperatures.

EtherCAT Solution

EtherCAT (Ethernet Control Automation Technology) is an industrial communication fieldbus built on the Ethernet network. In the realm of industrial automation, EtherCAT has emerged as the mainstream choice with its ultra-fast and real-time communication capabilities, aligning perfectly with the industry's pursuit of high precision, high efficiency, and cost-effectiveness.

ICP DAS provides customers with a comprehensive range of products such as master boards, motion controllers (EtherCAT master), and dozens of slave devices, offering compatibility with various brands. The master devices can update multiple slave devices in real time, with a cycle time of up to one millisecond. This functionality enables various applications, including motion control for 32-axis devices and multiple groups of single-axis devices.

Some ICP DAS EtherCAT master series follow the IEC 61131 standard and include SoftPLC functions, enabling customers to integrate EtherCAT slave devices of different brands easily. For slave devices, ICP DAS offers I/O modules, junction modules, converters, gateways, motion control modules, etc.

Devices included in ICP DAS EtherCAT solutions have successfully undergone tests using EtherCAT Conformance Test Tool (CTT), ensuring that various EtherCAT servo drives used can be integrated with third-party EtherCAT products. The flexibility allows users to choose any EtherCAT components as required with no compatibility issues.

ICP DAS provides customers with a comprehensive range of products such as master boards, motion controllers (EtherCAT master), and dozens of slave devices, offering compatibility with various brands. The master devices can update multiple slave devices in real time, with a cycle time of up to one millisecond. This functionality enables various applications, including motion control for 32-axis devices and multiple groups of single-axis devices.

Some ICP DAS EtherCAT master series follow the IEC 61131 standard and include SoftPLC functions, enabling customers to integrate EtherCAT slave devices of different brands easily. For slave devices, ICP DAS offers I/O modules, junction modules, converters, gateways, motion control modules, etc.

Devices included in ICP DAS EtherCAT solutions have successfully undergone tests using EtherCAT Conformance Test Tool (CTT), ensuring that various EtherCAT servo drives used can be integrated with third-party EtherCAT products. The flexibility allows users to choose any EtherCAT components as required with no compatibility issues.

OPC UA / MQTT Solution

OPC UA I/O module is a series of IIoT Ethernet I/O modules, known as UA I/O or U-7500 Series. The series features a built-in OPC UA Server and MQTT Client, and provides a web-based interface for module configuration, output channel settings, and monitoring module connections and I/O status.

The series supports functions of OPC UA Server and MQTT Client (both can run simultaneously) for IIoT communications, offering convenience of sending values of I/O channels to cloud-based IT systems or field control systems to read/write I/O and Virtual points. AI/AO modules support Scaling, allowing analog signals to be converted into more readable values.

The series supports functions of OPC UA Server and MQTT Client (both can run simultaneously) for IIoT communications, offering convenience of sending values of I/O channels to cloud-based IT systems or field control systems to read/write I/O and Virtual points. AI/AO modules support Scaling, allowing analog signals to be converted into more readable values.